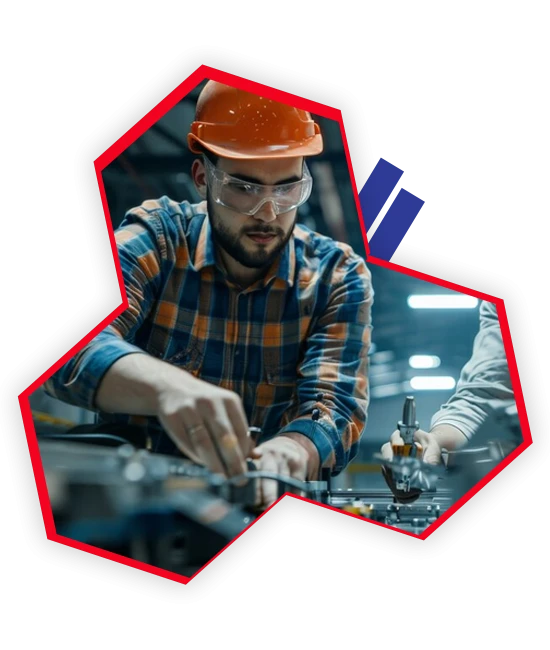

Quality Always Matters

Quality checks in CNC machine manufacturing are the ultimate assurance of precision and reliability throughout the production process. Every step is meticulously planned and executed to ensure that each component meets stringent quality standards and customer expectations.

Beginning with critical dimension verification, advanced metrology tools are employed to meticulously measure and inspect each part. This ensures that dimensional tolerances are strictly adhered to, guaranteeing proper fit and functionality within larger assemblies.

Surface finish assessment plays a crucial role in both aesthetics and functionality. Through meticulous inspection, the quality of surface finishes is evaluated to meet specified standards, enhancing both appearance and performance of the final product.